Serving you for over 20 years

m² of manufactured products

satisfied customers

completed projects

THERMOWOOD PRODUCTION

FOR EXTERIOR AND INTERIOR FINISHING

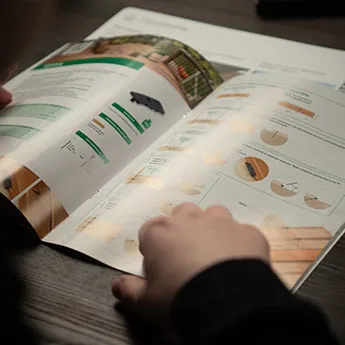

Thermodecking offers an extensive range of thermally treated wood materials from the finest grades and species of wood.

Our offerings include cladding (siding), decking and thermowood for interior decoration of the new generation at optimal prices with a guarantee from the manufacturer.

WHY CHOOSE US?

Our patented WestWood technology allows for heat treatment at temperatures ranging from 185 to 205 °C, imparting unique properties to the wood and rendering it essentially everlasting—an environmentally friendly material.

PRODUCTION STAGES

At the intersection of nature and cutting-edge heat treatment technologies, our company has crafted a distinctive product – thermowood.

Unlike regular wood, thermowood boasts geometric stability, reduced hygroscopicity, enhanced durability, and a distinctive natural wood texture. All these qualities position it as the wood of the new generation.

We source our timber from harvesting bases located in the Krasnodar and Irkutsk regions.

Our commitment to excellence begins with the meticulous selection of raw materials, adhering to the highest standards set by Thermodecking.

Only carefully chosen raw materials align with our technology’s criteria for heat-treatment, emphasising the pivotal role of the raw material base in achieving a superior finished product.

Specifics

of the production

cycle

High level

of forest

bonitet

Increased wood density

Comprehensive

control of all

production cycles

We source our timber from harvesting bases located in the Krasnodar and Irkutsk regions.

Our commitment to excellence begins with the meticulous selection of raw materials, adhering to the highest standards set by Thermodecking.

Only carefully chosen raw materials align with our technology’s criteria for heat-treatment, emphasising the pivotal role of the raw material base in achieving a superior finished product.

Specifics

of the production

cycle

High level

of forest

bonitet

Increased wood density

Comprehensive

control of all

production cycles

Utilising precision machinery and regularly maintained equipment, our sawing process minimizes waste through advanced technical capabilities.

Rigorous control of timber provided for sawing enables us to produce diverse, high-quality products, ensuring efficiency and accuracy.

Specifics

of the production

cycle

Quality

sawing

equipment

Uninterrupted

supply of wood

to drying chambers

Timely maintenance

Utilising precision machinery and regularly maintained equipment, our sawing process minimizes waste through advanced technical capabilities.

Rigorous control of timber provided for sawing enables us to produce diverse, high-quality products, ensuring efficiency and accuracy.

Quality

sawing

equipment

Uninterrupted

supply of wood

to drying chambers

Timely maintenance

Specifics

of the production

cycle

An uninterrupted delivery of raw materials to the chambers is integral to wood drying quality. Thermodecking specialists meticulously monitor all key stages of raw material preparation, reacting promptly to production situations.

Our team comprises top-notch specialists with extensive professional experience.

Specifics

of the production

cycle

Even and smooth drying

Uninterrupted chamber operation

State-of-the-art drying technology

An uninterrupted delivery of raw materials to the chambers is integral to wood drying quality. Thermodecking specialists meticulously monitor all key stages of raw material preparation, reacting promptly to production situations.

Our team comprises top-notch specialists with extensive professional experience.

Even and smooth drying

Uninterrupted chamber operation

State-of-the-art drying technology

Specifics

of the production

cycle

Distinguished by a thorough treatment throughout the entire thickness of the product, our WestWood heat treatment technology spans a 36-hour cycle, increasing the service life by tenfold compared to market analogues. Our specialists, continuously upgrading their skills and exchanging experiences with American counterparts, position Thermodecking at the forefront of heat treatment technology in Russia.

Specifics

of the production

cycle

Proprietary patent for technology

18 years of experience with thermowood

Production volume over 300 m3/month

Distinguished by a thorough treatment throughout the entire thickness of the product, our WestWood heat treatment technology spans a 36-hour cycle, increasing the service life by tenfold compared to market analogues. Our specialists, continuously upgrading their skills and exchanging experiences with American counterparts, position Thermodecking at the forefront of heat treatment technology in Russia.

Proprietary patent for technology

18 years of experience with thermowood

Production volume over 300 m3/month

Specifics

of the production

cycle

Our warehouse in Lukhovitsy holds over 3,000 m3 of sawn timber. To enhance customer convenience, we maintain a showroom and a transit warehouse in Moscow (Sormovsky proezd, 7a, bldg. 2), offering product samples and expert advice.

Specifics

of the production

cycle

6 hectares of own infrastructure

Modern warehouse management

Process automation

Our warehouse in Lukhovitsy holds over 3,000 m3 of sawn timber. To enhance customer convenience, we maintain a showroom and a transit warehouse in Moscow (Sormovsky proezd, 7a, bldg. 2), offering product samples and expert advice.

6 hectares of own infrastructure

Modern warehouse management

Process automation

Specifics

of the production

cycle

In our showroom, a team of dedicated professionals awaits to guide and assist you in selecting the ideal solution for your project. We provide a comprehensive range of additional services, from project preparation to colouring, coating, delivery, and installation. Our clients do not just stay customers; they become our friends and partners for years to come.

Specifics

of the production

cycle

Direct-from-manufacturer prices

20-year warranty

Expert counselling and turnkey operation

In our showroom, a team of dedicated professionals awaits to guide and assist you in selecting the ideal solution for your project. We provide a comprehensive range of additional services, from project preparation to colouring, coating, delivery, and installation. Our clients do not just stay customers; they become our friends and partners for years to come.

Direct-from-manufacturer prices

20-year warranty

Expert counselling and turnkey operation

Specifics

of the production

cycle

TO DESIGNERS

AND ARCHITECTS

We craft distinctive thermowood to empower you to bring your boldest ideas to life!

Thermowood stands as the most enduring, eco-friendly, hypoallergenic, geometrically stable, and robust natural finishing material available today.

Yet, its most significant advantage lies in its aesthetic allure. With noble shades, soft natural wood halftones, and a serene texture, this material imparts a modern and stylish touch to any project.

Our company collaborates with top architectural and design studios, counting major construction firms among our esteemed partners.

We consistently bring to fruition designs of varying complexity, ensuring superior quality and timely delivery.

Video consultation

Video consultation