PIONEERING WOOD HEAT

TREATMENT SINCE 2003

We proudly hold the top position for hardwood heat treatment volumes in Russia.

Among our clients, there are individuals, architects, landscape design studios, and construction companies.

THERMODECKING -

THE LARGEST MANUFACTURER OF

THERMOWOOD CLADDING AND DECKING MATERIALS.

WE CRAFT WOOD FOR COMFORTABLE LIVING.

AMONG OUR CLIENTS, THERE ARE INDIVIDUALS,

ARCHITECTS, LANDSCAPE DESIGN STUDIOS,

AND CONSTRUCTION & TRADING COMPANIES.

KEY FIGURES ABOUT THE COMPANY

Thermodecking entered the market of thermally treated wood in 2003 and over the past 18 years has established an unrivalled leadership position among Russian companies.

Some of our key figures: over 350 completed cladding and decking projects, over 1,200 realised deals. More than 49,000 m² of manufactured products and over 750 satisfied customers.

We specialize in heat-treating various wood types, offering a diverse product portfolio across different categories for a wide range of applications.

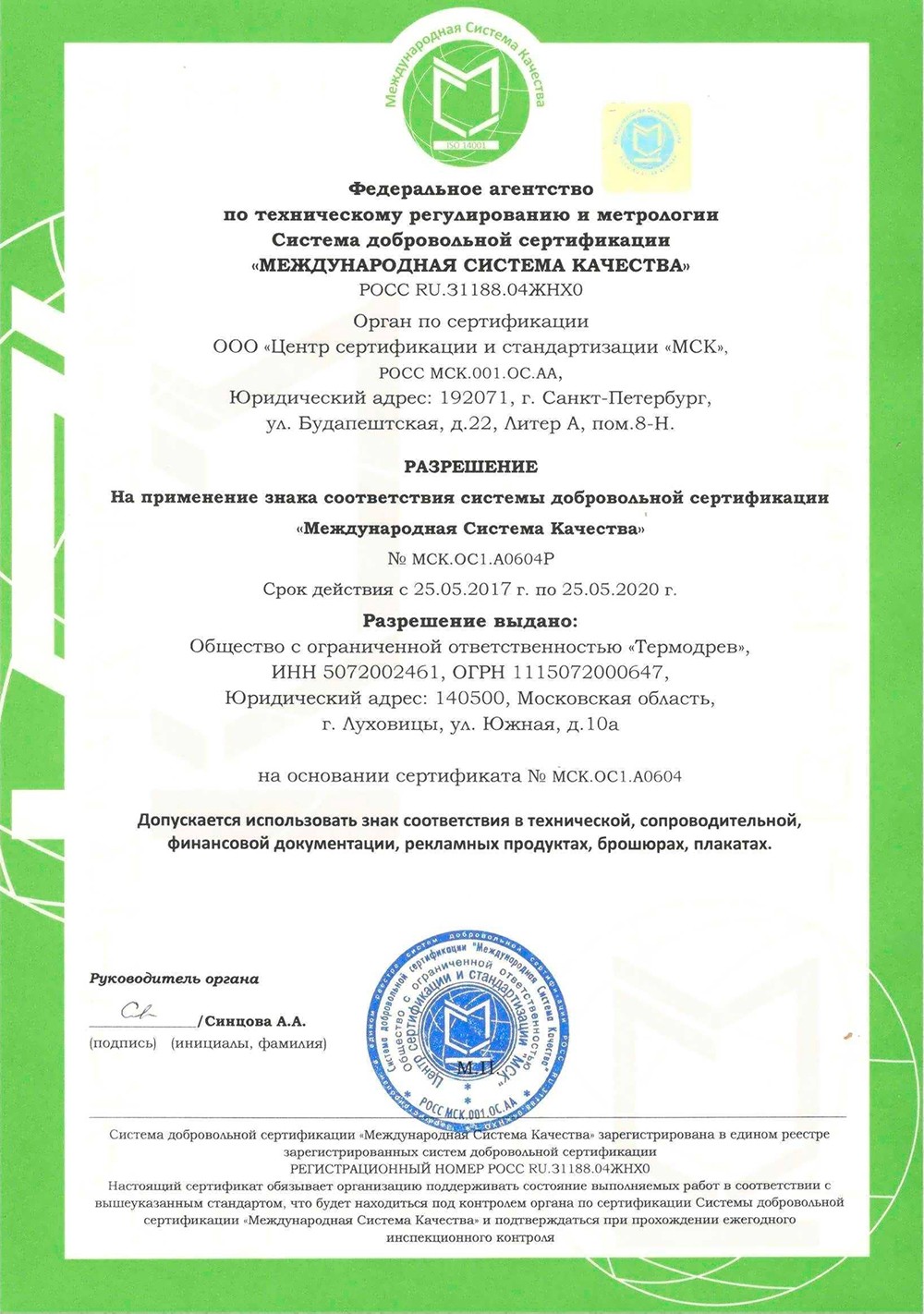

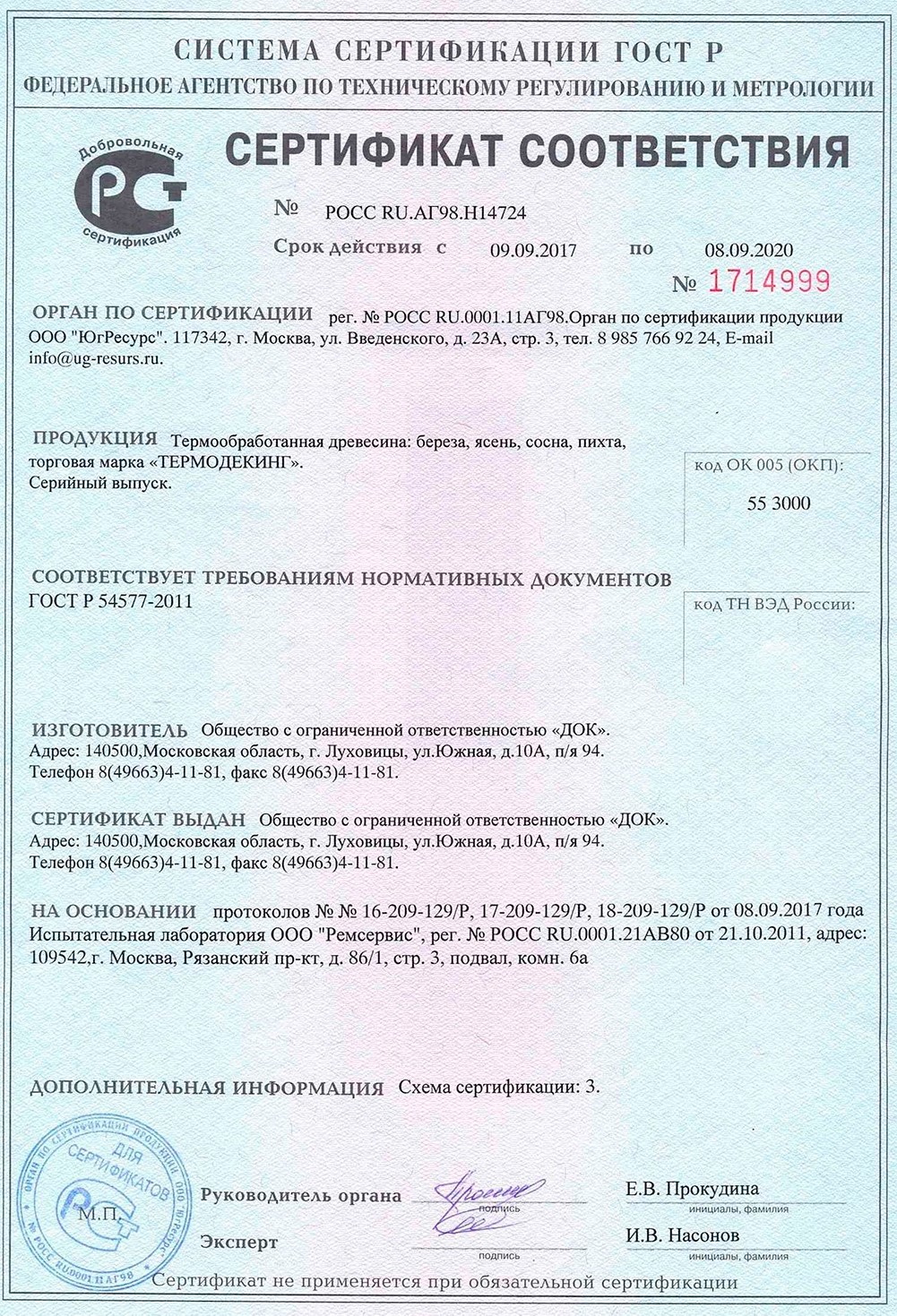

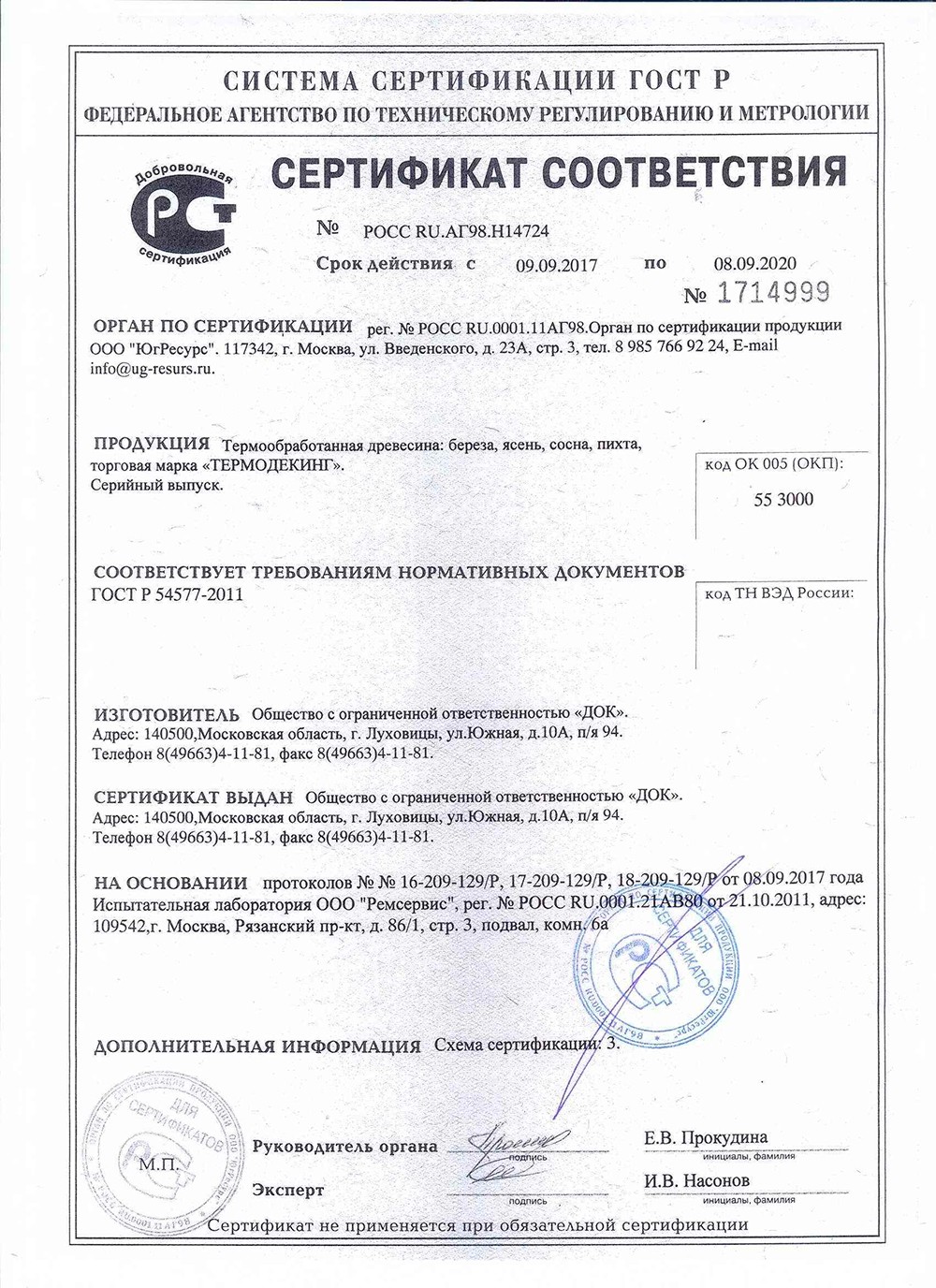

The Thermodecking company regularly takes part in various trade fairs and forums. The quality of our products is confirmed by numerous certificates, diplomas, and, above all, recommendations from our customers and partners. We have been awarded several prestigious titles, such as Product of the Year and Golden Brand.

In addition to manufacturing, we offer a comprehensive range of supplementary services such as planing, sanding, painting, packaging, and delivery. We transform bold ideas into accomplished projects, turning your dreams into reality.

MISSION

Natural wood that retains its best natural properties and remains unchanged and timeless for decades is not a dream, it is our mission. We produce thermowood to give you the opportunity to enjoy this high quality and durable natural material.

VALUES

Honesty and individual approach to each client. Our company does not take additional commissions and surcharges when selling products. We work with our own resources and respect the partnership with our suppliers. Working with us – very profitable!

GOAL

To consolidate our leading position in the market for premium heat-treated wood products. To increase growth rates and production volumes while maintaining high product and service quality.

interaction

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

High level of service

Customer interaction

Quality assurance from the market leader

Advice and customer support

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

We will help you choose the right material by highlighting the benefits of each species. We will show you samples of different colour shades to help you find the product that best suits your design project.

We can explore different price points, colour schemes and board sizes.

We will be happy to share all the secrets of how to best care for your new wooden interior, extending its lifespan to dozens of years.

Customer interaction

interaction

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

Turn-key operations

Customer interaction

Collaborations with architects and designers

Timely maintenance

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

We will help you choose the right material by highlighting the benefits of each species. We will show you samples of different colour shades to help you find the product that best suits your design project.

We can explore different price points, colour schemes and board sizes.

We will be happy to share all the secrets of how to best care for your new wooden interior, extending its lifespan to dozens of years.

Customer interaction

interaction

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

We will help you choose the right material by highlighting the benefits of each species. We will show you samples of different colour shades to help you find the product that best suits your design project.

We can explore different price points, colour schemes and board sizes.

We will be happy to share all the secrets of how to best care for your new wooden interior, extending its lifespan to dozens of years.

Delivery across Russia

Customer interaction

Office and warehouse in Moscow

Prices direct from the manufacturer

Our central office is located in Moscow, at 7A bldg. 2 Sormovsky proezd.

Our team of dedicated experts will provide you with a detailed consultation and calculations to help you choose the best thermowood facade board for your purposes. The Thermodecking experts will give you step-by-step recommendations to bring all your architectural and construction ideas to life.

We will help you choose the right material by highlighting the benefits of each species. We will show you samples of different colour shades to help you find the product that best suits your design project.

We can explore different price points, colour schemes and board sizes.

We will be happy to share all the secrets of how to best care for your new wooden interior, extending its lifespan to dozens of years.

Customer interaction

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

Quality control at all stages of production

Customer interaction

Automated heat treatment chambers

Chambers for gentle drying

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

Production features

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

State-of-the-art equipment

Production

High-quality raw materials

6 Ha property

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

Production features

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

Warehouse facilities

Production

Process automation

Advisory support from our joint venture in the USA

Our own production area spanning 6 hectares is located in Lukhovitsy, at 10a Yuzhnaya Street.

The main production areas:

1. Harvesting and initial drying to reduce the moisture content of the wood to 8-12%.

2. Heat treatment in high-tech automated chambers.

3. Manufacture of finished products.

4. Storage and logistics

Our company uses machinery and equipment specifically designed for working with thermowood. Timely maintenance of the machinery is one of our priorities.

The Technical Control Department monitors all orders and maintains management reporting in 1C. This helps us to meet international quality standards. Our own production infrastructure and continuous product quality control enable us to increase the volume of heat-treated timber every year. As a manufacturer, we can create complex and non-standard products for each customer individually. Our production capacity is 7,000-12,000 m2 per month. The volume of heat treatment is up to 500 m3 per month.

Production features

ORGANISATIONAL STRUCTURE

MEDIA ABOUT US

NTV home improvement show Dachni otvet

Thermodecking in the NTV home improvement show Dachni otvet

Pier, pergola and garden paths made of thermo birch

Video consultation

Video consultation